Our work and processes

Our approach to decarbonization

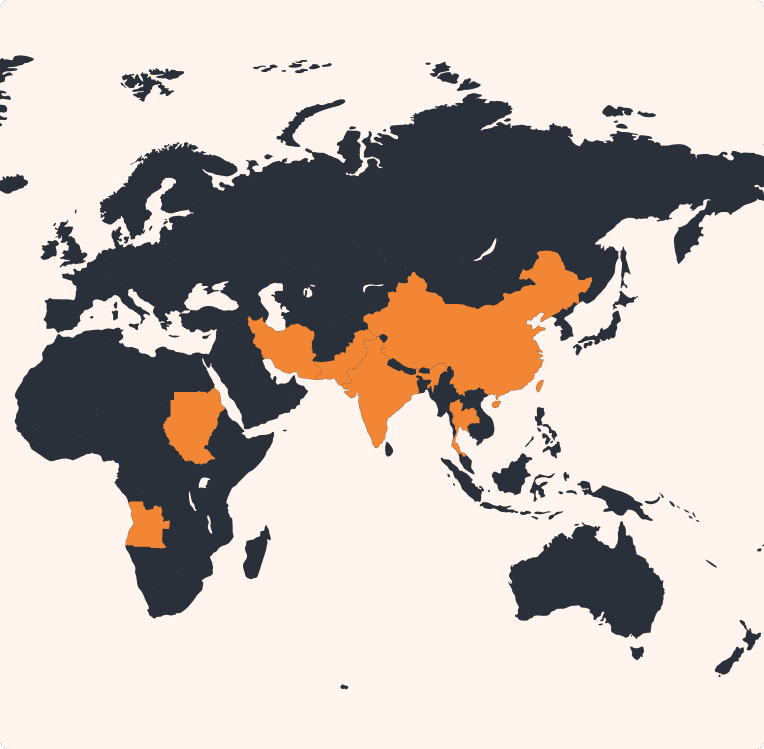

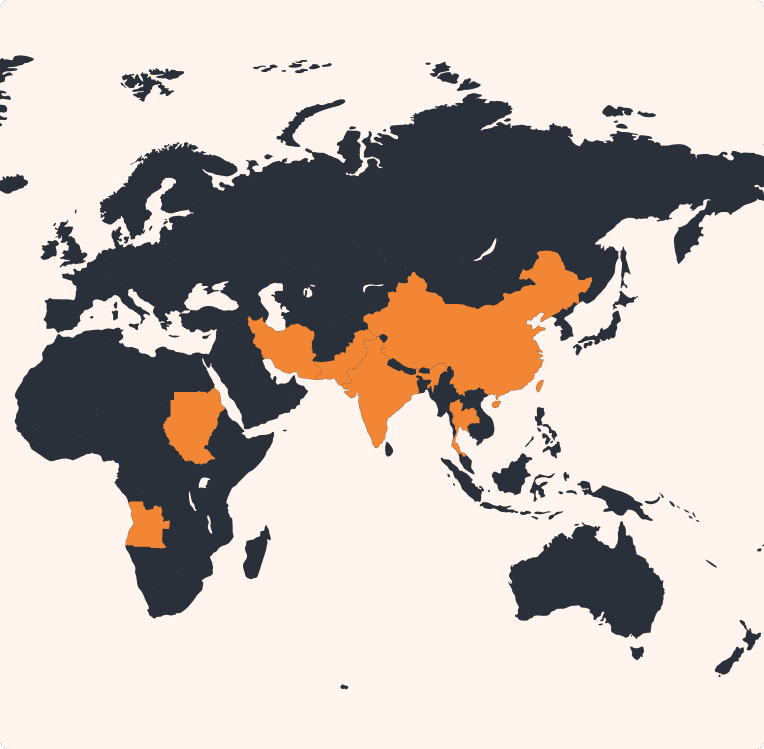

Guided by our criteria of effectiveness, reach, and scale, we leverage data to identify solutions that stand to make a meaningful carbon reduction in textile production. We use this portfolio of solutions to help suppliers create customized decarbonization plans, implement programs, and secure financing for improvements.

IDENTIFY

FUND

Scale

Measure

Identify

Fund

Scale

Measure

AII’s CLIMATE ACTION APPROACH

Our products and services

Benchmark: Carbon tech assessment

We conduct a comprehensive analysis of a company’s greenhouse gas emissions across its operations - including manufacturing, transportation, and energy use - to identify areas with the highest emissions.

Target setting: Carbon target setting

Based on CTA data, companies establish ambitious, measurable sustainability targets, such as achieving carbon neutrality, reducing emissions by a set percentage, or transitioning to renewable energy.

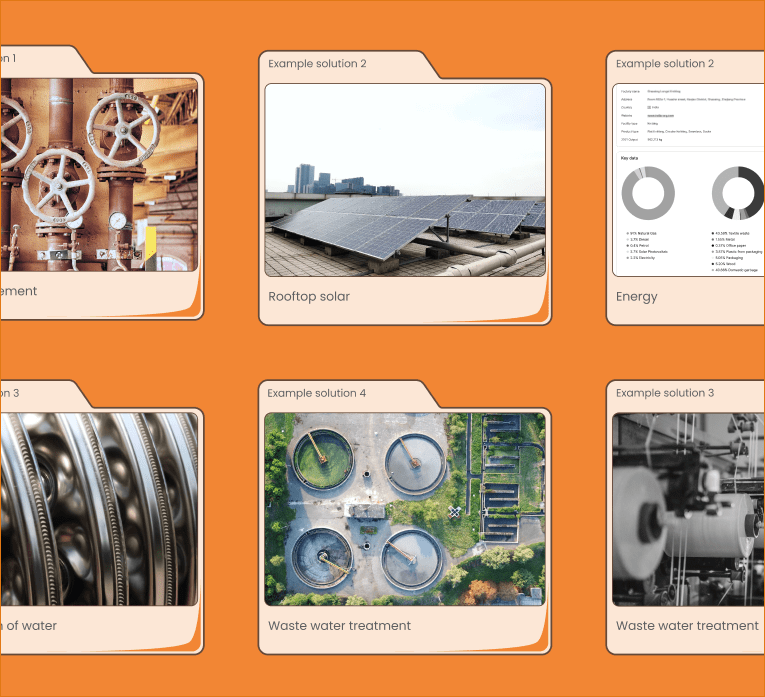

implementation: Aii climate solutions portfolio and programs

Leveraging our registry of vetted decarbonization solutions, companies select and implement those that fit. The registry includes Aii programs (e.g., Clean by Design) and CSP solutions that meet our high standards for effectiveness, reach, and scale.

carbon target monitoring: Carbon inventory, action plan

Aii provides ongoing support to companies as they implement their action plan, refining the plan as needed and offering regular touch points, progress follow-up, and technical assistance.

Data validation

Data validation, critical for supporting carbon accounting, is in the conceptual phase. We’re collaborating with industry stakeholders to align on principles, ensuring accurate and reliable carbon data.