Compare Applications

Registry only applications

Open

No scheduled close date for applications.

open

Targeted call for grants

Open

Applications open through January 2.

Targeted call for grants

open

Applications open through January 2.

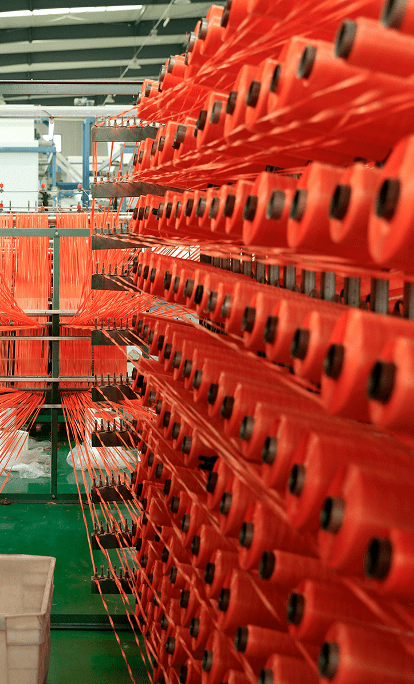

Supplier Electrification grant

We are looking for electrification and electrification supporting processing technologies that need pilots and demonstrations to enable scale by 2030. We have $1.335m available in grant funding for suppliers pursuing electrification or electrification-supporting projects. This application will be open November 3 - January 2.

We define electrification-supporting processing technologies as those that either electrify a process or significantly reduce the thermal need of a process. Our aim is to support 3-5 of the following project types:

-

- Steam generating heat pumps (provide steam above 120 degree and good COP, aiming for greater than 2.5)

- Low-energy dyeing solutions

- Digital spray dyeing

- Spray dyeing

- Electrification of bleaching

- Electric singeing

- Digital dyeing & coating

- Foam dyeing

Grant timeline

application resources

APPLICATION SUPPORT

The Climate Solutions Portfolio Advisory Council evaluates applications according to the requirements set out in the Grant Funding Thesis with a focus on effectiveness, reach, and scale. Please review the Thesis for additional information.

Yes, the application automatically saves and you can come back to it as needed until you are ready to submit.

Please follow the link the Submittable website for guidance if you are having difficulty with your application.

The data presented by a CSP Grant or Registry applicant will differ according to the solution’s maturity level. For Grant applications, where we accept less mature solutions, we are looking for a strong case to be made for the effectiveness of a solution. For a Registry application, we seek evidence that the solution delivers the expected effectiveness. Below we have outlined the maturity definitions and how this relates to the data.

- Pre-seed: Solutions at a concept level and in the process of evaluating and establishing their impact potential. The impact figures on these solution pages are indications of the solution's impact at this concept phase based on sources such as lab tests or a literature review.

- Pilot: Solutions testing to demonstrate a proof of concept. The impact figures on these solution pages are projections of the pilot's impact and do not yet reflect consistent performance.

- Model: Solutions working towards de-risking and reducing known barriers to scale. The impact figures on these solution pages are averages based on data from several pilots but do not yet represent a wide data set. Therefore, the actual impact may vary.

- Scale: Solutions that are commercially viable with a proven go-to-market strategy. The impact figures on these solution pages are averages based on data from numerous site-level implementations. Please note that the actual impact will be based on site-specific conditions and performance.

Registry Applications are reviewed on a rolling basis and you should hear back within 1-2 months of applying. If you have applied for a grant, you will receive an automatic email once you have applied on the review timelines. These can also be found in the application hub.