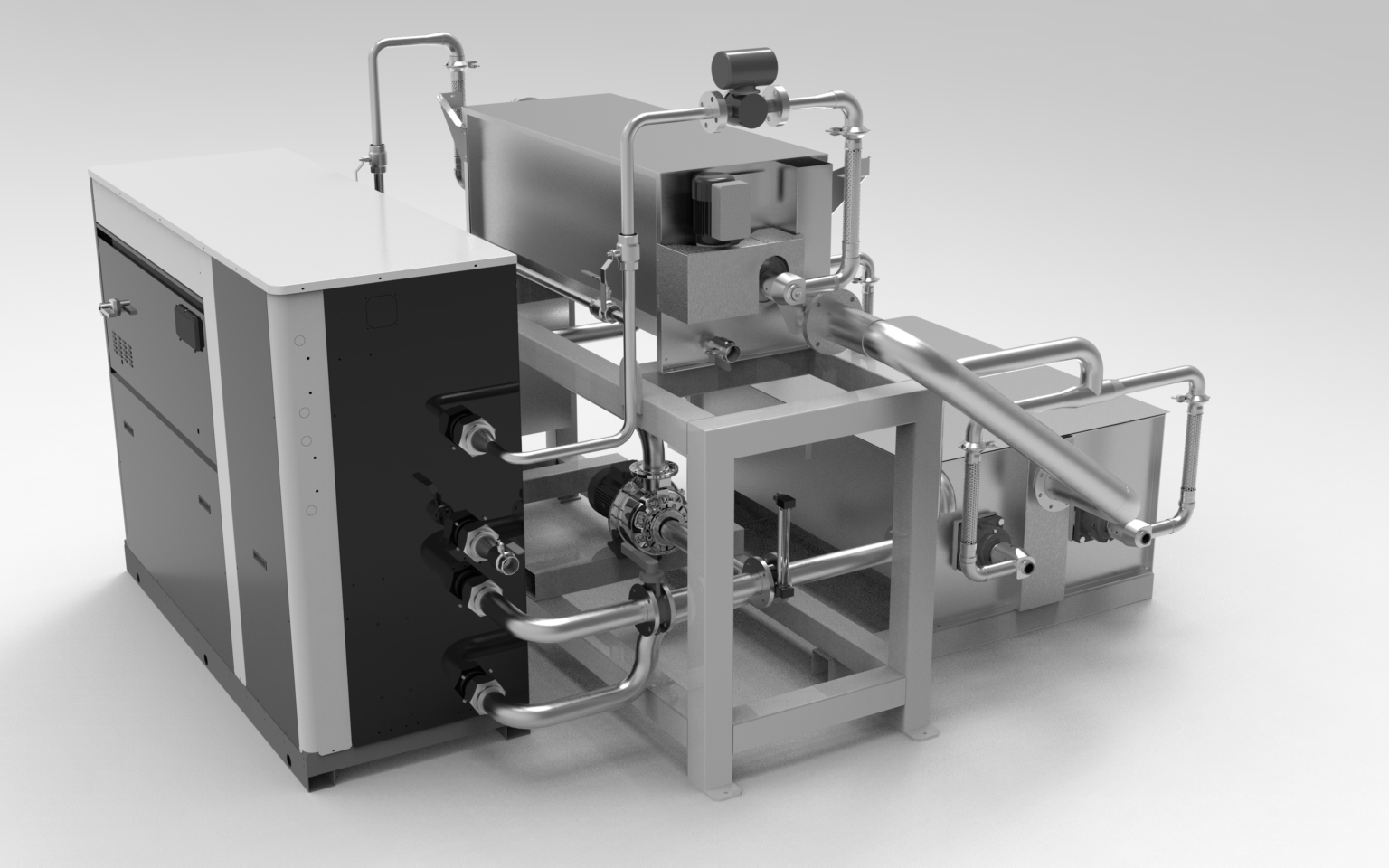

Pozzi's technology reduces GHG emitted by generating heat using waste water and electricity. The electrification hot water preparation can significanrtly reduce the high need of fossil sources for heat in the industry. By using a patented exchanger for challenging fluids and a heat pump, Pozzi significantly reduces reliance on fossil fuels in wet processing. The grant will support implementation in 15 mills. This will derisk the technology and support scaled deployment.

LEARN MORE ABOUT OUR MATURITY LEVELS

LEARN MORE ABOUT OUR MATURITY LEVELS5 associated sites

5 associated sites

5 associated sites