2024Yearly Report

ANNUAL IMPACT REPORT

Download PDF

Our Programs and Processes

Our Supplier Journey

This map has replaced our previous five-step Climate Action Approach and offers a simplified framework to guide our teams and brands through the daunting challenge of significant carbon reduction.

SUPPLIER PIPELINE

Back-end: Supplier Data File

We are building a data-based system that meets suppliers where they are on their journey. The cornerstone of our system is a robust supplier data file, and the tools to filter and analyze supplier data.

To meet our goals, we will need to improve our conversion rate for current and past suppliers. We know suppliers face several barriers to implementation and we should focus our efforts on supporting them through their journey.

To meet our goals, we will need to improve our conversion rate for current and past suppliers. We know suppliers face several barriers to implementation and we should focus our efforts on supporting them through their journey.

SUPPLIER

ENGAGEMENT

ENGAGEMENT

We decided that all suppliers must have an assessment and a target before starting implementation. If suppliers come into the Aii system with existing targets, roadmaps or action plans, we will accept these if they meet our criteria.

SUPPLIER

IMPLEMENTATION

IMPLEMENTATION

We are taking a more modular and solution-oriented approach to meeting supplier needs—not constrained to how we’ve historically bundled solutions inside programs.

This system can and should evolve over time, but we want to create a predictable cycle of updates for our processes and tools to create stability.

This system can and should evolve over time, but we want to create a predictable cycle of updates for our processes and tools to create stability.

Supplier Pathways

We have built a supplier-centric, data-based system to support suppliers through one of three pathways toward their decarbonization goals.

PATHWAY 1:

Past or Current Aii Supplier Participants

We strengthen and enhance our relationship with suppliers thathave or are currently working with Aii, supporting them as they proceed to the next steps of their decarbonization journey.

PATHWAY 2:

Strategic Suppliers & Industry Decarbonization

We partner with suppliers that offer the greatest potential for reductions. Engaging with these suppliers is key to achieving our goal of enabling the reduction of 100 Mt of carbon.

PATHWAY 1:

Other Suppliers & Brand Nominations

Working alongside our brand partners, we engage with suppliersthat are either not currently working with Aii or are considered an industry strategic supplier. This pathway allows Aii to support suppliers that may have completed action plans elsewhere. By implementing their existing plans, suppliers can continue their reduction efforts rather than starting from scratch.

These three pathways will allow us to take a more modular,solution-oriented approach to meeting suppliers’ needs ratherthan being constrained by programs.

These three pathways will allow us to take a more modular,solution-oriented approach to meeting suppliers’ needs ratherthan being constrained by programs.

Supplier Implementation

Suppliers complete a questionnaire — the Carbon Tech Assessment (CTA) — which undergoes an expert review. At this stage, we identify the supplier’s baseline, determine their maturity level, and offer estimated carbon reduction potential.

The next stage is long-term action planning, which is the foundationfor decarbonization implementation. Aii offers two options: Carbon Target Setting (CTS) and Best Practices Action Plan (BPAP).

CTS¹⁰ and action plan development are designed for higher energy consumers and carbon emitters, specifically large mills, dye houses,and garment washing plants. CTS starts the supplier on the mid-term journey to Net Zero with specific process- and regionally-focusedcarbon reduction solutions.

BPAP, in partnership with RESET Carbon, was successfully piloted in 2024to provide a “lighter-touch” action plan development program more suited to garment production units and facilities without wet processing operations. The BPAP program focuses on industry best practices, renewable energy opportunities, and machinery upgrades.

CTS¹⁰ and action plan development are designed for higher energy consumers and carbon emitters, specifically large mills, dye houses,and garment washing plants. CTS starts the supplier on the mid-term journey to Net Zero with specific process- and regionally-focusedcarbon reduction solutions.

BPAP, in partnership with RESET Carbon, was successfully piloted in 2024to provide a “lighter-touch” action plan development program more suited to garment production units and facilities without wet processing operations. The BPAP program focuses on industry best practices, renewable energy opportunities, and machinery upgrades.

Phase 2 focuses on activating the longer term targets intoimplementation. During this phase, suppliers implement the actions on their plan, which may include Clean by Design or programs and technologies in our Climate Solutions Portfolio.

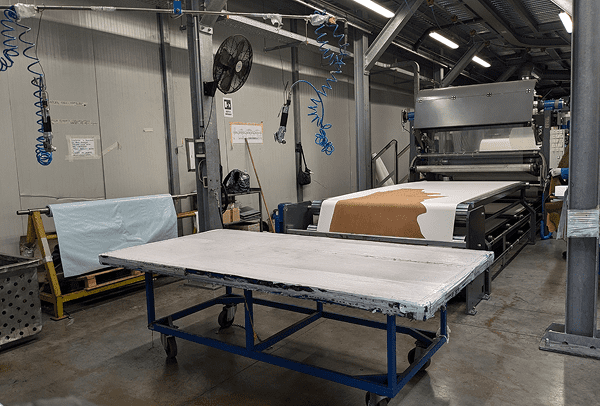

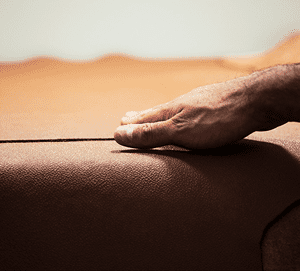

Implementation can be categorized into resource efficiency, renewable energy and reducing energy demand. Our efforts on resource efficiency expanded this year, not only to include registered CSP solutions such as Smartex and Tianfu technology, but also within our own programs. Clean by Design has extended into leather tanneries, with initial results showing tremendous opportunities for decarbonization and efficiency improvements.

In the renewable energy category, we completed our RETI pilots whichwill move to a full launch in China in 2025 alongside energy solutions pilots in Vietnam and India.

To reduce energy demand, we’ve begun registering solutions in this category — like Cleankore and Zydex — in the CSP. The CSP has adedicated section in this report due to its significance in achieving our vision and mission.

Implementation can be categorized into resource efficiency, renewable energy and reducing energy demand. Our efforts on resource efficiency expanded this year, not only to include registered CSP solutions such as Smartex and Tianfu technology, but also within our own programs. Clean by Design has extended into leather tanneries, with initial results showing tremendous opportunities for decarbonization and efficiency improvements.

In the renewable energy category, we completed our RETI pilots whichwill move to a full launch in China in 2025 alongside energy solutions pilots in Vietnam and India.

To reduce energy demand, we’ve begun registering solutions in this category — like Cleankore and Zydex — in the CSP. The CSP has adedicated section in this report due to its significance in achieving our vision and mission.

Suppliers participate in our Carbon Target Monitoring (CTM) program — in association with the brands — for continuous improvement and action plan implementation. Through quarterly online check-ins and progress reviews, an expert continues to provide advice, data monitoring, solutions updates, and regional and industry knowledge to facilitate further carbon reduction.

10. Previously Step 2 in our Climate Action Approach

Our Programs and Solutions

To visualize the comprehensive nature of our programs and solutions, we’ve compiled an overview of the tiers and impact areas addressed by each. This overview also incorporates our CSP Solutions, which are an integral part of Implementation (Phase 2), providing you with a holistic understanding of the full scope of our initiatives.

Case Study /

AURO

Case Study /

Collaborative Decarbonization

Case Study Auro: Driving Change Beyond Compliance

Challenge

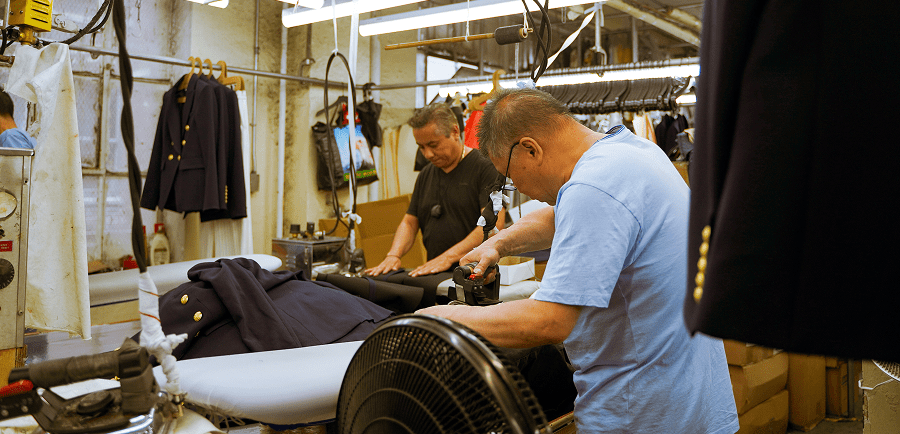

With 1.2 million spindles, Vardhman Textile, Ltd. is one of India’s production powerhouses, offering spinning and fabric operations for renowned high-end Indian brands and international household names.

But, with their large scale also came a significant environmental footprint. Auro Textiles, a unit of Vardhman, has been actively working to reduce their emissions for years; however, in 2021, the growing number of brands setting ambitious Scope 3 decarbonization targets presented an opportunity to accelerate progress in three key areas: energy use, natural resource consumption, and chemical impact.

No change comes without its challenges, and for Auro, that was modernizing their operations — many of which relied on older equipment — while balancing environmental impact and financial sustainability.

But, with their large scale also came a significant environmental footprint. Auro Textiles, a unit of Vardhman, has been actively working to reduce their emissions for years; however, in 2021, the growing number of brands setting ambitious Scope 3 decarbonization targets presented an opportunity to accelerate progress in three key areas: energy use, natural resource consumption, and chemical impact.

No change comes without its challenges, and for Auro, that was modernizing their operations — many of which relied on older equipment — while balancing environmental impact and financial sustainability.

Action

A referral from a brand partner led Auro to Aii and our Clean byDesign program.

Once connected to the Aii team and our local experts, Auro began establishing baselines for their facilities. Through thorough assessments of the plant’s energy and environmental performance, the Auro team identified critical areas for improvement. Aii and the experts thenprovided a comprehensive, data-driven roadmap, that includes bothhigh- and low-investment options, empowering Auro to prioritize projects based on their budget and goals. The process was streamlined, systematic, and straightforward.

Results came quickly: Following the experts’ recommendations,Auro began insulating boilers. The team noted that beyondemissions reductions, the change boosted their bottom line by saving steam and water, and enhanced employee safety by reducing injuriesand overheating.

Once connected to the Aii team and our local experts, Auro began establishing baselines for their facilities. Through thorough assessments of the plant’s energy and environmental performance, the Auro team identified critical areas for improvement. Aii and the experts thenprovided a comprehensive, data-driven roadmap, that includes bothhigh- and low-investment options, empowering Auro to prioritize projects based on their budget and goals. The process was streamlined, systematic, and straightforward.

Results came quickly: Following the experts’ recommendations,Auro began insulating boilers. The team noted that beyondemissions reductions, the change boosted their bottom line by saving steam and water, and enhanced employee safety by reducing injuriesand overheating.

Their work is resonating with their customers as well. As Auro continues updating its metrics on the Higg Index, they’ve earned praise frompartner brands, further motivating the Auro team to aim for even greater levels of efficiency.

But one of the biggest successes has been how this work has energized employees. By working with Aii and local experts, team members have gained valuable skills in process optimization and developed a stronger sense of ownership over the company’s decarbonization efforts. Connecting their day-to-day tasks to the company’s environmentalgoals has made their work more meaningful, leaving them motivatedand proud to drive positive change.

But one of the biggest successes has been how this work has energized employees. By working with Aii and local experts, team members have gained valuable skills in process optimization and developed a stronger sense of ownership over the company’s decarbonization efforts. Connecting their day-to-day tasks to the company’s environmentalgoals has made their work more meaningful, leaving them motivatedand proud to drive positive change.

What's Next

Working side-by-side with Aii and our network of experts has inspired Auro to set a concrete, ambitious decarbonization target through SBTi. Once that target is finalized, they’ll continue to work intensively on all fronts: from electricity to coal, water, steam consumption, and eco-friendly chemistry.

Driving change beyond compliance

Auro’s successes show the impact that systemic, data-driven approaches can have in meeting — and exceeding — environmental goals. If you’re ready to accelerate your decarbonization journey, please contact us at info@apparelimpact.org to explore how we can work together to fashion a better future.

Case Study: Collaborative Decarbonization

Achieving decarbonization at scale requires more than individual action - it demands coordinated efforts across the entire supply chain. In this fireside chat, Aii brings together leaders from Smartex, Acatel, and Impetus to explore how collaboration is accelerating progress toward their climate goals.

Our Programmatic Highlights

Türkiye Investigation Trip

In 2023, Aii launched a research initiative focused on identifying key emitting countries, using a comprehensive global factory dataset.Türkiye emerged as a focal point due to its significant potential forcarbon reduction. Boasting a diverse manufacturing ecosystem spanning from raw materials to finished goods, the country’s reliance on fossil energy underscores the urgency for targeted interventions to address emissions and facilitate a transition towards low-carbon practices.

Aii’s leadership sought deeper insights into opportunities and needs identified during the earlier research phase. In April 2024, our regional lead in Italy, Daniele Massetti, and our president, Lewis Perkins, visited Istanbul and Ergene. This visit united a network of suppliers, associations, and brands committed to collectively accelerating decarbonization roadmaps and adopting a standard and recognized approach tosupport Türkiye’s many SMEs.

Due to the successful outcome of the trip, we have selected anexpert and established pricing structures in Türkiye. We will open forfacility enrollment in 2025.

Aii’s leadership sought deeper insights into opportunities and needs identified during the earlier research phase. In April 2024, our regional lead in Italy, Daniele Massetti, and our president, Lewis Perkins, visited Istanbul and Ergene. This visit united a network of suppliers, associations, and brands committed to collectively accelerating decarbonization roadmaps and adopting a standard and recognized approach tosupport Türkiye’s many SMEs.

Due to the successful outcome of the trip, we have selected anexpert and established pricing structures in Türkiye. We will open forfacility enrollment in 2025.

In 2023, Aii launched a research initiative focused on identifying key emitting countries, using a comprehensive global factory dataset.Türkiye emerged as a focal point due to its significant potential forcarbon reduction. Boasting a diverse manufacturing ecosystem spanning from raw materials to finished goods, the country’s reliance on fossil energy underscores the urgency for targeted interventions to address emissions and facilitate a transition towards low-carbon practices.

Aii’s leadership sought deeper insights into opportunities and needs identified during the earlier research phase. In April 2024, our regionallead in Italy, Daniele Massetti, and our president, Lewis Perkins, visited Istanbul and Ergene. This visit united a network of suppliers, associations, and brands committed to collectively accelerating decarbonization roadmaps and adopting a standard and recognized approach tosupport Türkiye’s many SMEs.

Due to the successful outcome of the trip, we have selected anexpert and established pricing structures in Türkiye. We will open forfacility enrollment in 2025.

Aii’s leadership sought deeper insights into opportunities and needs identified during the earlier research phase. In April 2024, our regionallead in Italy, Daniele Massetti, and our president, Lewis Perkins, visited Istanbul and Ergene. This visit united a network of suppliers, associations, and brands committed to collectively accelerating decarbonization roadmaps and adopting a standard and recognized approach tosupport Türkiye’s many SMEs.

Due to the successful outcome of the trip, we have selected anexpert and established pricing structures in Türkiye. We will open forfacility enrollment in 2025.

Luxury Focus in Italy

Italian manufacturers and major luxury brands are becoming increasingly aware of the need and available opportunities for decarbonization. We have therefore expanded our program offerings in Italy and are offering tailor-made support with our regional lead in Italy.

Key Achievements

- 50 new facilities initiated program work,

- Four new brands started a collaboration with Aii,

- In response to the luxury sector’s needs, product categories were expanded to tanneries, jewelry, eyewear, and metal hardware.

- In addition to the strategic partnership with our CTS implementation partner Process Factory, a new strategic collaboration with Leyton has been established to support Aii in new product categories and implementation programs such as CbD.

As Italy is a country of innovative solutions with long-standing machine manufacturers, Aii’s work in the luxury goods sector value chain in 2025 will focus on solution research, recruitment, and implementation. We expect to significantly grow the number of suppliers starting programs and brands supporting the work. To support this increase, events for engagement and dissemination will be arranged.

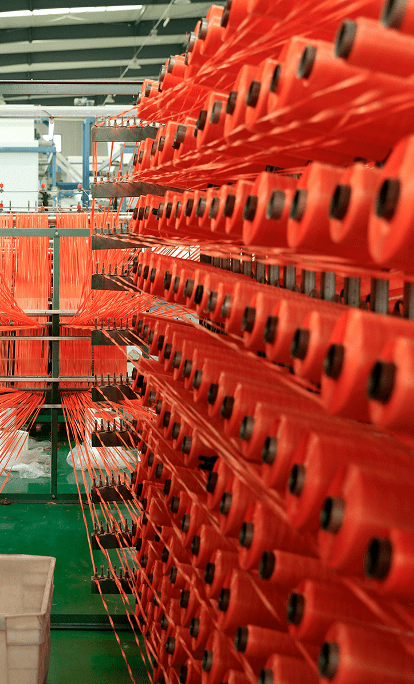

Shengze Initiative

In response to the urgent need for sustainable practices in the textile industry, Aii, in partnership with Shengze Town Government, Suzhou Rural Commercial Bank, and GIZ, has launched an initiative to drive the green transformation of Shengze — a key textile hub in China. Our collective mission is to foster innovation, enhance collaboration, and elevate the global standing of Shengze, renowned for its silk production and weaving, as a leader in sustainable textiles.

This initiative calls on all textile enterprises to engage in the transition towards green production by adopting cleaner technologies and improving energy efficiency. It aims to establish a comprehensive green manufacturing system, advance green textile technologies, and promote international environmental standards. By enhancing product quality and reducing carbon emissions, we seek to position ‘Shengze Weaving’ as a global benchmark for eco-friendly textiles. We invite all stakeholders to join us in leading the way toward a green, sustainable future for Shengze’s textile industry.

This initiative calls on all textile enterprises to engage in the transition towards green production by adopting cleaner technologies and improving energy efficiency. It aims to establish a comprehensive green manufacturing system, advance green textile technologies, and promote international environmental standards. By enhancing product quality and reducing carbon emissions, we seek to position ‘Shengze Weaving’ as a global benchmark for eco-friendly textiles. We invite all stakeholders to join us in leading the way toward a green, sustainable future for Shengze’s textile industry.

CbD Award Ceremony

The 2024 CbD Award Ceremony in Guangzhou marked a joyfuland long-awaited reunion for China’s manufacturers andbrand leaders who gathered in person for the first time since the COVID-19 pandemic. Representatives from more than 20 facilities and five major brands joined to celebrate. This year, 41 facilities achieved CbD program certification in China, with 14 earning top honors for excellence.

The award ceremony featured a presentation of Aii’s 2023 Impact Report and valuable insights from industry leaders on sustainability strategies. Selected facilities shared their journey with CbD programs, demonstrating the program’s significant impact on promoting sustainable development in the manufacturing sector.

The award ceremony featured a presentation of Aii’s 2023 Impact Report and valuable insights from industry leaders on sustainability strategies. Selected facilities shared their journey with CbD programs, demonstrating the program’s significant impact on promoting sustainable development in the manufacturing sector.

“What stands out is how our partners have evolved beyond compliance to become true sustainability champions, actively sharing their knowledge with industry peers.”

- AIMIN YANG,

General Manager, Hongyu

General Manager, Hongyu

Our Key Focus Areas

Based on the results of the highest emitters study mentioned in the Roadmap to 2030 section, we’ve identified and are focusing a large portion of our efforts on the key regions of China, India, Bangladesh, and Vietnam over the next 18 months.

China

China is the world’s leading producer and exporter of both textiles and garments, with 32.2% of the global market share. It is the largest supplier to many apparel-exporting countries, particularly those in Asia. China has the world’s largest and most complicated textile system, covering every stage from fiber, yarn, grey fabric, finished fabric, garment process, and distribution.

Challenges: Over the past two years, rising trade uncertainties have led many global brands to scale back textile and apparel sourcing from mainland China. Companies with overseas facilities are increasingly shifting orders and expanding production abroad. Favorable trade agreements in countries like Vietnam with markets in the US, Europe, and Japan have further accelerated this relocation of parts of China’s textile industry chain.

Facility tiers in these regions:

TIER 1 / TIER 2 / TIER 3 / TIER 4

TIER 1 / TIER 2 / TIER 3 / TIER 4

Key manufacturing areas

Facility tiers in these regions:

TIER 1 / TIER 2 / TIER 3 / TIER 4

TIER 1 / TIER 2 / TIER 3 / TIER 4

Key manufacturing areas

India

India is the fourth-largest exporter in the industry, with 4.36% of the global market share.¹³

India has a high potential for renewable energy, including solar and wind power, which could transform textile production if integrated into the sector.

India has a high potential for renewable energy, including solar and wind power, which could transform textile production if integrated into the sector.

Challenges: Manufacturers face many sustainability challenges due to constraints with financing, infrastructure, internal capacity, and enabling energy policies. Suppliers are often unaware of available technologies and financing mechanisms that could facilitate their transition to more sustainable practices. This knowledge gap inhibits their ability to make informed decisions regarding the adoption of energy-efficient machinery and renewable energy solutions.

Textile production in India relies heavily on coal-powered energy, particularly for processes like dyeing, spinning, and weaving. This reliance on fossil fuels contributes heavily to the industry’s carbon footprint.¹⁴

Textile production in India relies heavily on coal-powered energy, particularly for processes like dyeing, spinning, and weaving. This reliance on fossil fuels contributes heavily to the industry’s carbon footprint.¹⁴

12 Textiles (HS Section: XI) Product Trade, Exporters and Importers | The Observatory of Economic Complexity

13 manufacturingtodayindia.com/the-role-of-renewable-energy-in-transforming-indias-manufacturing-sector

14 fibre2fashion.com/industry-article/9492/overcoming-energy-crisis-for-textile-manufacturing

Landscape and Opportunities to Finance the Decarbonization of India’s Apparel Manufacturing Sector | Apparel Impact Institute

13 manufacturingtodayindia.com/the-role-of-renewable-energy-in-transforming-indias-manufacturing-sector

14 fibre2fashion.com/industry-article/9492/overcoming-energy-crisis-for-textile-manufacturing

Landscape and Opportunities to Finance the Decarbonization of India’s Apparel Manufacturing Sector | Apparel Impact Institute

Bangladesh

Bangladesh is the second-largest exporter in the industry with 6.13% of the global market share.

Industry activities in this region include activities ranging from raw material processing to the production of ready-made garments. With a rapidly expanding market for clean energy and energy efficiency, Bangladesh is uniquely poised to lead the charge in sustainable manufacturing and trade.

Industry activities in this region include activities ranging from raw material processing to the production of ready-made garments. With a rapidly expanding market for clean energy and energy efficiency, Bangladesh is uniquely poised to lead the charge in sustainable manufacturing and trade.

Challenges: The apparel and textile industry is a major contributor to Bangladesh’s economy – bringing in more than 80% of the country’s foreign export revenue. Yet, it is also a source of significant environmental problems. Local production processes heavily depend on fossil fuels, mainly natural gas, which contributed 51% of the country’s primary energy in 2021. Aside from GHG emissions, other environmental concerns include water effluent pollution and waste management. Manufacturers face considerable challenges in transitioning to sustainable operations due to financial and incentive constraints, limited internal capabilities, insufficient energy policies, and inadequate infrastructure within the energy sector.¹⁶

15 Textiles (HS Section: XI) Product Trade, Exporters and Importers | The Observatory of Economic Complexity

16 Investing in Sustainability: Opportunities to Finance Decarbonization in Bangladesh’s Apparel and Textile Industries; Apparel Impact Institute

16 Investing in Sustainability: Opportunities to Finance Decarbonization in Bangladesh’s Apparel and Textile Industries; Apparel Impact Institute

Facility tiers in these regions:

TIER 1 / TIER 2 / TIER 3

TIER 1 / TIER 2 / TIER 3

Key manufacturing areas

Facility tiers in these regions:

TIER 1 / TIER 2 / TIER 3 / TIER 4

TIER 1 / TIER 2 / TIER 3 / TIER 4

Key manufacturing areas

Vietnam

Vietnam is the third-largest industry exporter, with 5.18% of the global market share.¹⁸

The country’s textile industry has grown significantly since the late 1990s. Now it’s the second-largest contributor to Vietnam’s export revenue. Vietnam primarily exports to the US, EU, Japan, South Korea, and China, making it an important player in the global market.

The country’s textile industry has grown significantly since the late 1990s. Now it’s the second-largest contributor to Vietnam’s export revenue. Vietnam primarily exports to the US, EU, Japan, South Korea, and China, making it an important player in the global market.

Challenges: Vietnam’s textile industry has some big hurdles to overcome. High energy use and carbon emissions are major issues, especially in Tier 2 processes like dyeing and finishing, which are energy-intensive. Renewable energy is still hard to access in many areas, though government programs are slowly improving this. Challenges are particularly noticeable in dyeing which requires significant amounts of water and generates large volumes of wastewater. Factories are facing additional pressure as the government implements stricter regulations for wastewater and chemical use.¹⁹

Our 2024 Pilot Programs

We’ve undertaken multiple pilot projects throughout 2024, enabling us to test, refine, and optimize strategies before moving to the model stage for full-scale adoption. Our team closely supports and evaluates these pilots, extracting insights for continuous improvements and enhanced approaches.

Best Practices Action Plan (BPAP)

BPAP is a shorter, more focused, and lighter-touch program for Tier 1 facilities to establish an appropriate Action Plan for Decarbonization, with a specific focus on machinery upgrades, renewable energy opportunities, and coal elimination.

Key Achievements

- 68 suppliers started a BPAP program in 2024 with 26 completing it by the end of the year.

Key Learnings

- Peer group training sessions of participating facilities provided a valuable cross-pollination of information regarding the suitability and availability of solutions.

- Online interviews with the energy expert and Tier 1-focused group webinar sessions have successfully delivered tailored action plans.

Renewable Energy Transition Initiative (RETI) in Mainland China, South and Southeast Asia

The Renewable Energy Transition Initiative (RETI) plays a crucial role in supporting large-scale traditional printing and dyeing facilities in adopting renewable energy technologies alongside conventional energy sources. These facilities have significant energy demands, and while equipment upgrades can reduce some energy consumption, they fall short of fully meeting the carbon reduction goals set by brands. Aii, in collaboration with Levi Strauss & Co. and Gap, initiated the pilot phase of RETI in 2022, targeting eight key supply chain facilities located in the Yangtze and Pearl River Deltas in Mainland China.

In partnership with Beijing Jingneng Power, RETI seeks to help manufacturers identify and implement renewable energy solutions.The program begins with thorough data collection and evaluates14 renewable energy technologies based on policy maturity, technology readiness, and factory conditions. From this, the most suitable renewable energy technologies are recommended, focusing on clean electricity generation and clean thermal energy solutions. Throughout the implementation process, RETI conducts on-site assessments to track progress, ensuring that renewable energy technologies, policies, and business models are seamlessly integrated to support the apparel industry’s green transformation and carbon reduction efforts.

In partnership with Beijing Jingneng Power, RETI seeks to help manufacturers identify and implement renewable energy solutions.The program begins with thorough data collection and evaluates14 renewable energy technologies based on policy maturity, technology readiness, and factory conditions. From this, the most suitable renewable energy technologies are recommended, focusing on clean electricity generation and clean thermal energy solutions. Throughout the implementation process, RETI conducts on-site assessments to track progress, ensuring that renewable energy technologies, policies, and business models are seamlessly integrated to support the apparel industry’s green transformation and carbon reduction efforts.

Moving forward to 2025, Aii will formally launch the RETI program beyond the pilot phase to Mainland China and South and Southeast Asia, and expand its scope to include a broader range of renewable energy technologies beyond solar. A three-part audit mechanism involving the brand, Aii, and the facility itself will be implemented to ensure transparency, consistency, and precise evaluation of carbon reductions across all energy sources. This approach will strengthen the program’s value and guide future expansion.

Key Achievements

- 8 pilot phase facilities have achieved a total reduction of 107,730 tonnes of CO2e with an average saving per facility of 3.28%.

Key Learnings

- From a project-wide perspective, the RETI program has highlighted the significant potential of solar PV power generation to reduce carbon emissions for large-scale facilities. However, challenges remain in establishing clear guidelines for the ownership and allocation of carbon reduction rights. Without standardized calculations and explicit agreements, issues such as double counting, restricted carbon reduction benefits, and challenges in achieving sustainability targets may arise.

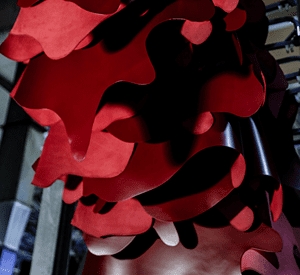

Clean by Design for Tanneries (CbD Tanneries)

CbD for tanneries was kicked off in June 2024, with a group of 11 tanneries engaged by four luxury brands sharing a vision towards decarbonizing the industry through collective action. Product categories covered not just apparel, but also footwear, leather garments, handbags, and accessories.

Key Achievements

- Potential GHG savings have been identified for 11 active Italian tanneries.

- The pilot phase has been successfully completed, and the program will move to scale in mid-2025 with new brands and facilities in Italy, and France.

Key Learnings

- Despite the high performance of Italian tanneries, additional efficiency measures have been identified — particularly, wider adoption of best practices and a more systematic approach to energy and water efficiency.

“Tre Effe Conceria was invited in early 2024 to take part in the CbD for tanneries program by a group of luxury brands, which joined forces to scale decarbonization solutions along the leather supply chain. The unified and aligned request from the brands towards the same direction has given significant impetus, clarity, and strength to the initiative.

Thanks to the systematic framework of the CbD for tanneries program, we have now identified innovative win-win solutions for energy efficiency and renewable energy, allowing us to save costs and significantly reduce CO2 emissions. We are excited to continue this path movingto the implementation phase.”

Thanks to the systematic framework of the CbD for tanneries program, we have now identified innovative win-win solutions for energy efficiency and renewable energy, allowing us to save costs and significantly reduce CO2 emissions. We are excited to continue this path movingto the implementation phase.”

- AIMIN YANG,

General Manager, Hongyu

General Manager, Hongyu

Expansion to New Regions in Africa/Middle East

In 2025, we are looking to recruit and onboard experts to deploy programs to facilities in newly developing textile regions including Jordan, Egypt, Kenya and Ethiopia and established regions including Morocco, Madagascar and Mauritius. The primary focus will be assessments and target setting through CTA/CTS and evaluating renewable energy opportunities in these regions.

Ouarzazate Solar Power Station, also called Noor Power Station is a solar power complex and auxiliary diesel fuel system located in the Drâa-Tafilalet region in Morocco, 10 kilometres from Ouarzazate town, in Ghessat rural council area. At 510 MW, it is the world’s largest concentrated solar power plant.

Photo by MohssinDr, Wikimedia Commons

Photo by MohssinDr, Wikimedia Commons

Climate Solutions Portfolio

Aii’s Climate Solutions Portfolio is the apparel and textile industry’s registry for vetted climate solutions. It simplifies and accelerates the adoption of proven and promising solutions — innovations, projects, or programs — that create a positive impact and deliver measurable CO2e reductions.We achieve this by offering grant funding to less mature solutions, vetting mature solutions, and amplifying both on our Climate Solutions Portfolio registry. Through our programs, network of brands and suppliers, and blended capital strategy we facilitate and support the deployment and scale of these solutions.

Grants

Open Call Application Process Update

Our Grant Funding Thesis, which clarifies what we fund, was published in January 2024 in preparation for our March 1 open call for applications. The thesis proved to be a helpful tool as we received fewer but stronger applications more closely aligned with our strategic priorities. We also made the following amendments to the application process:

- Introduced the Ready Reckoner: Solution Impact Evaluator. This tool enabled all applications to use standardized baselines at the subprocess level to calculate their impact. It also created a uniform approach to estimating scale and impact.

- With the Ready Reckoner, we also began communicating solution impact on a per kg of production approach. Again, this standardized impact figures across not only the same baseline, but also the same unit.

- The application was digitized and streamlined through Submittable, making the application and evaluation process much smoother.

We awarded three grants through the March 2024 open call.

“In this round of grants, we bridged innovation gaps by supporting solution innovators who have leading-edge, impactful, and practical technologies. Collectively, these solutions have the potential to reduce 24,407 tCO2e within the first 12 months of project implementation,”

said Aii’s Chief Impact Officer, Kurt Kipka.

Overview of 2024 Grantees

- Pozzi, established in 1885, has a long-standing tradition in the manufacturing of machines for the textile industry, with a particular emphasis on the wet processing sector. The company is spearheading a feasibility study across 15 facilities to evaluate, demonstrate, and eventually scale low-carbon alternative solution RHeX+HP, a heat recovery system designed to overcome clogging and efficiency loss with traditional heat exchangers. The aim of this grant is to enhance energy recovery through heat pump integration, with the potential to save 20,546 tCO2e within the first 12 months of project implementation.

- Grant Thornton is a community of almost 10,000 audit & assurance, tax and advisory problem solvers, relationship builders, and industry specialists with extensive experience in developing policies and supporting the implementation of climate change mitigation solutions. The awarded grant will enable the piloting and evaluation of innovative approaches within the lubricant industry, focusing on how mineral oil-based products can enhance energy conservation through reduced friction, improved temperature stability, and resistance to oxidation and contaminants. The project has the potential to save 136 tCO2e within the first 12 months of implementation. The insights gained will be used to create a Best Practices/Standard Operating Practices guide aimed at promoting these benefits across the industry.

- Amphico comprises a combination of experienced scientists and designers who are passionate about making the future a better place, both in creating less impactful materials for the planet and in the improved performance of the products they facilitate. Their solution combines dope-dyed yarns with optical color-mixing during weaving, where >6000 colors as woven fabrics are created from 6-10 primary-colored yarns. In contrast to other waterless textile coloration, their method does not require special & expensive equipment implementation; dope dyeing is possible by adding color-masterbatch during conventional yarn spinning, and optical color-mixing on industrial weaving machines Amphico will use the grant to expand color availability to 10,000 colors at an industrial scale, increasing adoption significantly. This project has the potential to save 3,725 tCO2e within the first 12 months of implementation.

2023 Grant Projects Update

Our 2023 open-call grantees have made substantial progress. A few of our projects anticipated a 2024 completion, but due to unforeseen circumstances they have incurred delays and will continue into 2025. Below we provide a short summary of each project’s status. For those further along in their project, we have provided a case study with a more detailed overview of learnings and outcomes.

- PwC worked with 10 companies, five each from India and Bangladesh, to implement cleaner production systems that reduce GHG emissions and water usage. The project covered viscose filament manufacturing, spinning, knitting, and wet processing, and prioritized process re-engineering, machinery upgrades with attachments/controls, digital technology adoption, and workforce training. With its potential for large-scale implementation in major textile manufacturing countries, lower investment requirements, and high-impact GHG emission reductions, this solution is attractive to brands, manufacturers, development agencies, and governments.

- PxD is halfway through its project and has distributed leaf color charts to 10,000 farmers. (case study below)

- Made2Flow has developed its recommendation engine and begun testing with a handful of facilities. This presents a new tool and opportunity for scaled facility engagement with impressive results. Brands are opting to use this remote tool to engage with smaller or less strategic suppliers, which has led to a more time-consuming enrollment and delays in the tool testing phase of the project. This project was due for completion in Q4 2024 but will roll over into 2025.

- Bluwin’s Clean By Design Bangladesh has experienced delays due to the political situation in Bangladesh. In-person visits are a core feature of the program, and they have required rescheduling. Additionally, facilities were facing more immediate priorities over the past year. Nonetheless, the action plans look very promising and we look forward to seeing them realized. This project was due for completion in Q4 2024 but will roll over into 2025.

- GIZ’s Solar PV Bangladesh is a three-year project that saw an above-expected enrollment in its first year, with over 30 facilities nominated for participation. By the end of Q4 2024, feasibility reports for five facilities were successfully completed, while three facilities utilized fast-track matchmaking services. Looking ahead, five additional feasibility reports are expected to be finalized and shared by the end of January 2025, and another 10 are anticipated to be completed by Q2 2025. This means 23 out of the 30 facilities will likely complete the program by the end of 2025, with seven factories requiring follow-up to ensure their participation. This project is on track and due for completion in Q3 2026.

Case Study: PxD

PxD’s leaf color charts project is Aii’s first engagement with T4 and it is proving to be a great success. Our colleague, Laxmikant Jawale, regional lead in South Asia and Southeast Asia, conducted a site visit during the training stage of the project. Field agents of Ambuja Foundation, a local organization that has become a key stakeholder in the project, received the trainer training so they could disseminate the leaf color charts before the sowing season started. Ten thousand farmers received access to leaf color charts in June so they could start their cotton growing season with optimal nitrogen application. The project has also gained a lot of traction with the local government agency VANAMATI, which is keen to see this approach to fertilizer management becoming a permanent fixture in the region’s farming practices. We are excited to see larger-scale impact after the program reaches an additional 20,000 farmers in 2025.

GHG calculations will begin as the growing season ends in March 2025. Preliminary data collection by the implementing partner, Ambuja Foundation, shows that a total of 26,961 cotton farmers have been ableto access LCCs through this program. This includes 9,689 ‘core’ farmers who directly received LCCs from the Ambuja Foundation and 17,272 farmers who borrowed LCCs from the core farmers. On average, each core farmer shared their LCC with approximately 2.3 other farmers. We are excited to see the CO2e reduction results.

GHG calculations will begin as the growing season ends in March 2025. Preliminary data collection by the implementing partner, Ambuja Foundation, shows that a total of 26,961 cotton farmers have been ableto access LCCs through this program. This includes 9,689 ‘core’ farmers who directly received LCCs from the Ambuja Foundation and 17,272 farmers who borrowed LCCs from the core farmers. On average, each core farmer shared their LCC with approximately 2.3 other farmers. We are excited to see the CO2e reduction results.

“I cultivate cotton in 3.5 acres of land. I significantly reduced the urea dosage in my 2nd fertilizer application based on the recommendation from LCC. I shared my LCC with five other farmers [in] my learning group, mostly my relatives and neighbors. I find the LCC sharing model to be quite effective. I did not face any issues in organizing training and demo sessions and coordinating with farmers who borrowed LCC from me.”

- PRIYANKA KAKDE, Lead farmer of an Ambuja Foundation farmer learning group, Panjari village, Hingna block, Nagpur district, Maharashtra

Summary Overview of All Grant Projects

Calculations are explained in the methodology section

Low Carbon Thermal Energy Roadmap

We are developing a low-carbon thermal roadmap to address the critical questions of when, where, and how to implement this transition. The report, originally due for release in November, will be published in March. An energy storage opportunity review is still ongoing.

In conjunction with the roadmap, Aii prepared a Low-Carbon Thermal Energy Strategy, outlined below.

In conjunction with the roadmap, Aii prepared a Low-Carbon Thermal Energy Strategy, outlined below.

Climate Solutions Focus

- Thermal Load Reduction: Aii will double down its programmatic and CSP Registry focus on solutions that reduce thermal energy needs in facilities. By reducing the thermal load, increased OPEX required for electrification decreases as facilities use less energy. Aii will support facilities in implementing solutions by providing brand-funded technical advice where needed and financial support for CAPEX investments. This initiative is under development, will be piloted in 2025, and will be ready for scaled deployment in 2026.

- Renewable Thermal Energy Transition: Piloted as the Renewable Energy Transition Initiative (RETI), this program will be formally launched in China and piloted in India and Vietnam in 2025. Starting in 2026, we will aim for scaled deployment across our focus regions to enable energy transition. This program provides technical feasibility assessments and implementation support for facilities seeking to transition to low-carbon thermal energy sources. In accordance with the findings from our Low Carbon Thermal Roadmap, the process will consider transitional fuel sources such as biomass only when certified supplies of sustainably-sourced feedstock can be assured. Due to future limitations of sustainable biomass supply, we do not see this as a long-term solution. Therefore the program will emphasize electrification technologies such as heat pumps, energy storage, and transitions to electric boilers.

- Climate Solutions Portfolio (CSP) Grant Funding: Aii will be using CSP grant funding to support suppliers, innovators, and OEMs to develop sufficient case studies for electrification and thermal load reduction technologies. The aim of these grants will be to generate learnings, remove obstacles, and reduce the price and risk associated with these technologies. Aii will disseminate learnings across the sector so that all stakeholders have a repository of information to support the low-carbon thermal energy transition.

- CSP Solutions Recruitment: In addition to supporting solutions with grants, Aii will also be recruiting solutions that don’t need grant funding. Many solutions that will support this sectoral transition are already commercially viable. Aii aims to help the sector prioritize solutions by conducting rigorous vetting — ensuring brands and suppliers can focus on implementation over evaluation. Aii does this through partnerships with organizations like Fashion for Good and its wide array of engineers delivering Aii’s work in sourcing regions.

Ecosystem Leadership

- Brand Market Signal: Aii will work with its brand ecosystem to develop support for the strategy and direction outlined in the Low Carbon Thermal Energy Roadmap, while also guiding brands on interim steps needed to activate this transition. Brands have a big role to play in policy advocacy, market signaling to OEMs, and long-term assurances of the direction of travel to suppliers.

- Renewable Electricity: Noting that the ability to procure renewable electricity is a core enabler of the low-carbon thermal energy transition, Aii will be exploring with its stakeholders to find the appropriate supporting role Aii can play.

- Financial Ecosystem Leadership: Using the Brand Finance Playbook, Aii will continue to drive brands to unlock the necessary budgets to support supplier decarbonization. Aii will also continue to facilitate collective financing among brands to increase the volume of textile manufacturers receiving technical and financial support.

Our Approach

In November 2024, we invited suppliers considering innovative electrification projects to apply for grant funding. This approach reflects our commitment to listening to the sector’s decarbonization experts: suppliers innovating their way to 2030 and beyond. Grantees will be selected in March 2025.

As part of the Low-Carbon Thermal Energy strategy, we identified the need to align on the definition of sustainable biomass and developed a hierarchy of low-carbon thermal solutions. This builds on existing industry alignment and was created in consultation with energy transition experts to drive the sector forward in a unified way.

As part of the Low-Carbon Thermal Energy strategy, we identified the need to align on the definition of sustainable biomass and developed a hierarchy of low-carbon thermal solutions. This builds on existing industry alignment and was created in consultation with energy transition experts to drive the sector forward in a unified way.

Registrants

Beyond offering grant funding to scale promising solutions and projects, the Climate Solutions Portfolio was designed to be a registry of proven solutions that can be immediately implemented. We are seeking solutions ready for scaled deployment to include in the registry. While the Registrant application links thematically to the grant funding thesis (i.e. what we want to register), it is focused solely on solutions at the model and scale maturity level. The Climate Solutions Portfolio registry can be found on the Aii website.

We were very excited to accept our first-ever Registrants to the Climate Solutions Portfolio this year. Our programs team has been working hard to integrate these Registrants into our programs to enable matchmaking through our facility work. We look forward to seeing the results of those efforts in 2025.

We were very excited to accept our first-ever Registrants to the Climate Solutions Portfolio this year. Our programs team has been working hard to integrate these Registrants into our programs to enable matchmaking through our facility work. We look forward to seeing the results of those efforts in 2025.

SMARTEX

AI-Enabled, Real-Time Quality Control

POTENTIAL SAVINGS: 0.058 kg CO2e/kg production

Visit Website

CLEAN KORE

Patented Ring Dyeing Technology

POTENTIAL SAVINGS: 0.77-0.87 kg CO2e/kg production

Visit Website

BLUESIGN

Bluesign System for Manufacturers

POTENTIAL SAVINGS: 0.03-0.24 kg CO2e/kg production

FOSHAN ASSOCIATION

Guangdong Energy & Water Efficiency

POTENTIAL SAVINGS: 0.05-0.55 kg CO2e/kg production

TIANFU TECHNOLOGY

Intelligent Facility Technology

POTENTIAL SAVINGS: 0.15-0.74 kg CO2e/kg production

Outlook 2025

Increased supplier-led approach

By having a balanced representation of brands and suppliers on our Climate Solutions Portfolio Advisory Council (CSPAC) we intend to increase our ability to select solutions that suppliers really need. This is consistent with Aii’s overall strategy of creating a pool of low-carbon suppliers.

We look to hear from suppliers who are at the forefront of innovation, testing technologies that can deliver real impact. We are excited to support their individual projects and act as the catalyst to disseminate learnings and share innovation across the supply chain.

We look to hear from suppliers who are at the forefront of innovation, testing technologies that can deliver real impact. We are excited to support their individual projects and act as the catalyst to disseminate learnings and share innovation across the supply chain.

Increased Supplier-Led Approach & Focus on Thermal Energy

As outlined earlier in this section, Aii’s CSP and programmatic offering will increasingly focus on reducing thermal energy consumption and transitioning those energy sources. This is the key area where we can deliver supplier impact. From the grant perspective, we continue to seek projects that will support electrification, whether through an innovative solution or the modification and evolution of existing processes. We will also continue to focus on process-level innovation and mature solutions that dramatically reduce a facility’s thermal needs.

“With the release of our roadmap we have a clear direction of travel for the sector’s largest supply chain emission source: thermal energy in wet processing facilities. It has been fascinating to develop this with GEI and to work with all our brand and supplier partners to strategize how Aii can most effectively help the sector achieve the vision outlined in this roadmap. In order to achieve this I look forward to continued engagement with suppliers and solutions providers in their great ideas and hope to see increased budgets from brands to support these projects. Without supply chain investment using the plays in our Playbook we cannot achieve the vision that the roadmap and our strategy has set out.”

- PAULINE OP DE BEECK, Climate Portfolio Director

CSP Registry

In 2023, Aii introduced the CSP platform, an all-in-one tool helping the industry discover emission reduction programs and solutions, manage the implementation of these programs, and report on their efficacy.

As Aii shifts to a more Digital Transformation strategy with technology, the CSP platform is being rebuilt for scale and enhanced on our main website. This process will streamline access to the tool for visitors to Aii’s public website.

As Aii shifts to a more Digital Transformation strategy with technology, the CSP platform is being rebuilt for scale and enhanced on our main website. This process will streamline access to the tool for visitors to Aii’s public website.

Sustainable Finance

Aii’s sustainable finance strategy connects suppliers to the financial support they need to reduce carbon emissions and help the industry achieve a 45-50% carbon reduction by 2030 and net zero by 2050. This approach is driven by a registry of enhanced financial solutions and matchmaking with financial institutions.

2024 Activities and Achievements

- Jointly launched the Future Supplier Initiative.

- Released the Brand Playbook for Financing Decarbonization.

- Conducted regional research and published country-specific landscape reports (additional information can be found in the Thought Leadership section of this report).

- Developed a registry of attractive financing solutions by region.

- Hosted activation events, including a strategic summit and a convening at New York Climate Week (additional information can be found in the Thought Leadership section of this report).

Future Supplier Initiative

The Future Supplier Initiative (FSI) was jointly launched in 2024 byThe Fashion Pact, Apparel Impact Institute, Guidehouse, and DBS Bank,with the ambition to accelerate supply chain decarbonization in the fashion industry. The initiative offers an innovative collective financing model to help apparel suppliers implement decarbonization strategiesto achieve near-term science-based targets.

The first FSI program is being explored in Bangladesh with the backing of leading fashion brands such as Bestseller, Gap Inc., H&M Group, and Mango — in collaboration with Asian Development Bank (ADB) and leading commercial banks with local presence — to advance sustainable financing solutions in critical apparel manufacturing regions.

The first FSI program is being explored in Bangladesh with the backing of leading fashion brands such as Bestseller, Gap Inc., H&M Group, and Mango — in collaboration with Asian Development Bank (ADB) and leading commercial banks with local presence — to advance sustainable financing solutions in critical apparel manufacturing regions.

“To achieve this industry’s ambitious climate goals, it’s imperative that every stakeholder leverages their influence to drive tangible change. A joint effort among brands and retailers is essential to create conditions where supppliers are motivated and capable of making these investments. Financial institutions are poised to offer better finance options provided there’s a robust pipeline of suppliers ready to embrace decarbonization efforts. The acceleration of these efforts occurs when the industry aligns its business strategies, resources and investments toward the most impactful solutions.”

- LEWIS PERKINS, CEO, Apparel Impact Institute

The Brand Playbook for Financing Decarbonization

Aii’s “Brand Playbook for Financing Decarbonization” outlines 12 financial strategies brands can undertake to encourage suppliers to invest in carbon reduction projects. It provides real-world examples, assessing the risks and benefits of each approach while recognizing the need for tailored strategies across different brands and retailers.

The playbook is intentionally presented using simple financialterminology in order to be accessible to brand sustainability andsourcing professionals and serve as a bridge between those teamsand brand finance. These teams must resolve their internal tensionsto start the flywheel of change, and being aligned on the availableoptions is a crucial first step.

The playbook was released during a live event at New York ClimateWeek, which included representatives from brands, suppliers, andfinancial institutions.

The playbook was released during a live event at New York ClimateWeek, which included representatives from brands, suppliers, andfinancial institutions.

Key Learnings

- Partnerships: Multi-stakeholder collaborations — such as partnerships between brands, suppliers, financial institutions, and government bodies — enable the pooling of resources, expertise, and influence, which is essential for scaling sustainable finance solutions.

- Long-Term Commitment and ‘Patient Capital’: Blended finance models benefit from investors willing to commit over the long term. Organizations like family offices, philanthropic funds, and development finance institutions (DFIs) can provide patient capital, facilitate pilot projects, and allow sustainable projects to mature without immediate pressures for high returns.

- Transparency and Reporting: Robust monitoring and reporting frameworks are crucial for tracking blended finance’s impact on Scope 3 emissions. Transparent reporting not only helps build trust among stakeholders but also demonstrates the feasibility and success of financing sustainable initiatives, encouraging further investment.

- Risk Mitigation: Blended finance solutions that diversify funding sources, such as integrating grants with commercial loans and impact investments, can help mitigate financial risks. It enables SME suppliers to access lower-than market-rate capital while reducing the financial burden on individual investors.

Outlook 2025

Industry experts agree that financing apparel manufacturing decarbonization will require innovative financial structures; collective industry action; and stronger engagement from brands, financial institutions, and government bodies to reach ambitious 2030 and 2050 climate targets.20 Aii will support the industry by expanding our regional research and publishing country-specific landscape reports for Bangladesh and China.

The Fashion Climate Fund will play a critical role by deploying $250 million in catalytic capital to attract an additional $2 billion for industry-wide decarbonization. Efforts like FSI and the Fashion Climate Fund, highlight a growing trend toward integrated, sector-wide financial solutions to make sustainable practices accessible for manufacturers, bridging the gap between climate goals and actionable financing models.

The Fashion Climate Fund will play a critical role by deploying $250 million in catalytic capital to attract an additional $2 billion for industry-wide decarbonization. Efforts like FSI and the Fashion Climate Fund, highlight a growing trend toward integrated, sector-wide financial solutions to make sustainable practices accessible for manufacturers, bridging the gap between climate goals and actionable financing models.

Thought Leadership

Aii Events

Second Annual Strategy Summit

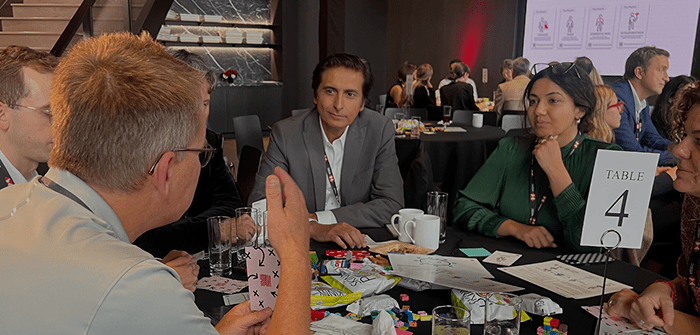

In March 2024, Aii gathered 80 stakeholders — including Aii board members, Fashion Climate Fund and brand partners, suppliers, financial institutions, and strategic collaborators — for three days of meetings, workshops, and focused conversations.

The event activated our strategy and made the kind of meaningful progress on initiatives that can only happen when stakeholdersare in the same room. The foundation of the summit was breakout sessions on the topics of Brand Commitment, Supplier Engagement, Decarbonization Solutions, Sustainable Finance, and Technology. Attendees reported that the event felt grounded in action and theright size to support focused collaboration.

The event activated our strategy and made the kind of meaningful progress on initiatives that can only happen when stakeholdersare in the same room. The foundation of the summit was breakout sessions on the topics of Brand Commitment, Supplier Engagement, Decarbonization Solutions, Sustainable Finance, and Technology. Attendees reported that the event felt grounded in action and theright size to support focused collaboration.

Global Impact Forum on Low-Carbon and Sustainable Transition of the Textile Industry

On October 18, 2024, the Shengze Town Government, Suzhou Financial Association, Suzhou Rural Commercial Bank, Apparel Impact Institute, and Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) jointly hosted the Global Impact Forum on Low-Carbon and Sustainable Transition of the Textile Industry in Shengze. This event coincided with the 13th Jiangsu (Shengze) Textile Expo and the 2024 Suzhou Bay Fashion Week, attracting approximately 90 guests from government, financial institutions, non-profit organizations, and the business sector to discuss pathways and challenges of low-carbon transformation in the textile industry.

At the forum, Kurt Kipka, our chief impact officer, highlighted global trends in sustainable development and identified three key factors driving industry transformation: collective action, policy guidance, and technological innovation.

Additionally, Anthony Wei, sustainability director of Decathlon, provided an overview of brand-level transformation experiences, and Jian Sun from the Shengze government elaborated on the regional initiatives and practices in green development. The diverse perspectives shared along the textile industry chain provided the attendees with valuable insights into the low-carbon transition.

A key moment at the forum was the collaborative launch of the initiative titled “Capacity Building on Low Carbon Transformation and International Influence of the Shengze Textile Industry.” This initiative, led by the Shengze Town Government, Suzhou Rural Commercial Bank, Aii, and GIZ, aims to enhance international influence in low-carbon transformation while exploring successful case studies within regional textile clusters.

The forum also included two dialogue sessions. Anzhou, our vice president of technology, led the industry session, focusing on “Impact and Paths to Achieve Low Carbon Sustainable Transformation in the Textile Industry from the Supply Chain Perspective.” This discussion brought together representatives from various sectors of the industry value chain — including brands, manufacturing companies, and international organizations — to explore the challenges and opportunities related to the industry’s transformation.

The forum showcased the active participation of stakeholders across the entire industry value chain and served as a valuable platform for communication and collaboration within the textile sector. The initiative fostered a positive environment for green development and encouraged new pathways for sustainable growth.

At the forum, Kurt Kipka, our chief impact officer, highlighted global trends in sustainable development and identified three key factors driving industry transformation: collective action, policy guidance, and technological innovation.

Additionally, Anthony Wei, sustainability director of Decathlon, provided an overview of brand-level transformation experiences, and Jian Sun from the Shengze government elaborated on the regional initiatives and practices in green development. The diverse perspectives shared along the textile industry chain provided the attendees with valuable insights into the low-carbon transition.

A key moment at the forum was the collaborative launch of the initiative titled “Capacity Building on Low Carbon Transformation and International Influence of the Shengze Textile Industry.” This initiative, led by the Shengze Town Government, Suzhou Rural Commercial Bank, Aii, and GIZ, aims to enhance international influence in low-carbon transformation while exploring successful case studies within regional textile clusters.

The forum also included two dialogue sessions. Anzhou, our vice president of technology, led the industry session, focusing on “Impact and Paths to Achieve Low Carbon Sustainable Transformation in the Textile Industry from the Supply Chain Perspective.” This discussion brought together representatives from various sectors of the industry value chain — including brands, manufacturing companies, and international organizations — to explore the challenges and opportunities related to the industry’s transformation.

The forum showcased the active participation of stakeholders across the entire industry value chain and served as a valuable platform for communication and collaboration within the textile sector. The initiative fostered a positive environment for green development and encouraged new pathways for sustainable growth.

Engagement Days

In 2024 we conducted three “engagement days” events to better serve our global stakeholders. These events took place over 2-3 days, with multiple webinar options available live and on-demand. The theme for our 2024 engagement days was “Evolving for Impact Towards 2030,” with subthemes for each quarter:

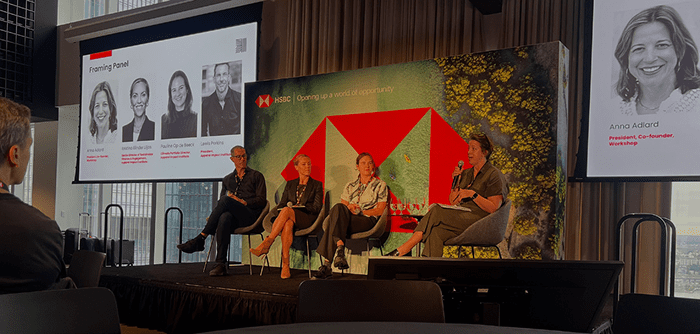

New York Climate Week

During New York Climate Week in September 2024, Aii hosted two gatherings for more than 80 participants at HSBC’s New York office. Our first activation provided orientation and framing around the cost of decarbonization and the role of catalytic capital. We hosted a perspectives panel with representatives from the supply chain, brands, banks, and philanthropy. Then, we spent the afternoon introducing the audience to the Brand Playbook for Financing Decarbonization and explored the report’s concepts in a unique game format. On the second day, we broke into three sessions, diving deep into existing initiatives in Sustainable Finance, Decarbonization Solutions, and Brand Commitment.

Both Aii president, Lewis Perkins, and senior director of sustainable finance and engagement, Kristina Elinder Liljas, participated in several speaking engagements, joining panels at events hosted by Pakistan Environmental Trust, The Fashion Pact, and Cascale.

Aii was also featured this year as a Clinton Global Initiative commitment-maker and pledged $2M from the Fashion Climate Fund as first-loss funding to unlock other asset classes and provide affordable financing to suppliers.

Both Aii president, Lewis Perkins, and senior director of sustainable finance and engagement, Kristina Elinder Liljas, participated in several speaking engagements, joining panels at events hosted by Pakistan Environmental Trust, The Fashion Pact, and Cascale.

Aii was also featured this year as a Clinton Global Initiative commitment-maker and pledged $2M from the Fashion Climate Fund as first-loss funding to unlock other asset classes and provide affordable financing to suppliers.

External Events & Stakeholder Engagement

Bangladesh Climate Forum

“Participating in the first panel discussion of the day, joined by delegates from The World Bank, BGMEA (Bangladesh Garment Manufacturers and Exporters Association), Target Sourcing, and The Sustainable & Renewable Energy Authority, our lively discussion around “Unblocking Decarbonisation Roadblocks” really drilled down on actionable solutions to reduce the technological, financial, infrastructure, and policy gaps that are slowing the transition to a low-carbon apparel industry in Bangladesh.

In addition to the presentations and panel discussions, this event was an exciting opportunity to connect with brands, manufacturers, government and non-government agencies, technology suppliers, and other stakeholders with a vested interest in reducing the carbon impact of the apparel industry in Bangladesh”

In addition to the presentations and panel discussions, this event was an exciting opportunity to connect with brands, manufacturers, government and non-government agencies, technology suppliers, and other stakeholders with a vested interest in reducing the carbon impact of the apparel industry in Bangladesh”

LISA FROST, Climate Programs Director

COP29

Lewis Perkins, Aii president, and Kristina Elinder Liljas, senior director of sustainable finance and engagement, attended COP29 this year. Lewis and Kristina both participated in speaking engagements, including a conversation hosted by TrustTrace about data-driven decarbonization; a fireside chat at the World Climate Summit on building responsible supply chains; and a panel at Financial Times’ FT Sessions to discuss safeguarding water, communities, and biodiversity.

Lewis also appeared onstage at the Climate Action Innovation Zone’s Sustainable Investment Forum to share insights on best practices for energy transition in hard-to-abate sectors.

Lewis also appeared onstage at the Climate Action Innovation Zone’s Sustainable Investment Forum to share insights on best practices for energy transition in hard-to-abate sectors.

Cascale Annual Meeting

Chief Impact Officer, Kurt Kipka, spoke at Cascale’s Annual Meeting alongside Liam Salter (CEO, RESET Carbon) and Andrew Martin (executive vice president, Cascale) to introduce the Industry Decarbonization Roadmap — a joint effort to expedite the industry’s decarbonization efforts by addressing the most strategic suppliers with an opportunity for significant reductions and a standardized process.

Global Fashion Summit

The Global Fashion Summit consistently draws influential industry leaders, providing unique opportunities for direct, one-on-one engagement with top brands, suppliers, and ecosystem innovators.

“This year, I found particular value in the Summit’s side sessions which are recognized for their hands-on, practical approach. I represented Aii at the Future Supplier Initiative roundtable, followed by a panel, where we reviewed and discussed fashion’s emissions data, challenges, and the roadmap to net zero.”

- ANDRES BRAGAGNINI, Manager of Strategic Engagement

UNFCCC Fashion Charter Annual Meeting

“During the UNFCCC Annual Fashion Charter meeting, we focused on refining the 2030 strategy to better align with industry needs and reaffirm brand signatory commitments. Key outcomes included recalibrating the Charter’s purpose to support signatories more effectively and recognizing its untapped potential for policy influence. We also introduced new workstreams, particularly around financing decarbonization and increasing engagement with finance sector stakeholders. Governance updates, including a shift to a project-based approach, will be shared soon, and at Aii, we reaffirm our position as a key supporting organization to the Charter.”

- ANDRES BRAGAGNINI, Manager of Strategic Engagement

Media Highlights

Eight major press announcements/ pitches

(in comparison to six in 2023)

- March 8: Aii Appoints Hasitha Premaratne to Board of Directors (media advisory)

- March 15: Aii Releases 2023 Impact Report, Showcasing Progress In Its Sustainability Goals (media advisory)

- May 7: Apparel Impact Institute Provides Platform for Impactful Carbon-Reducing Solutions, Invites Innovations to Register for CSP (media advisory)

- May 16: Road to Net Zero: Apparel Impact Institute Shares Annual Report on Industry Progress (press release)

- August 13: Can the fashion industry help vulnerable countries meet their NDCs? (pitch)

- September 10: Apparel Impact Institute Announces Additional $1M in Catalytic Grants to Decarbonize Fashion Supply Chains (press release)

- September 17: Apparel Impact Institute Launches New Roadmap to Accelerate Supply Chain Decarbonization (press release)

- November: $2.5 Billion Available to Fund Sustainable Practices in India, According to New Report (press release)

0

TOTAL STORIES

Data & Reporting

Taking Stock of Progress Against the Roadmap to Net Zero 2024

In 2021, Aii and the World Resources Institutepublished “Roadmap to Net Zero,” a reportevaluating the apparel industry’s emissionsand calling for system-wide, collective actionto reduce emissions by 45 percent by 2030and to net zero by 2050.

We have promised to refresh this analysis annually using the best available data, andhave therefore published the 2024 sequel,Taking Stock of Progress Against the Roadmapto Net Zero 2024. As with the original report, Aiiused data from Cascale, Worldly, and TextileExchange – with revised assumptions – torefresh the GHG estimate for the apparel sector.

We have promised to refresh this analysis annually using the best available data, andhave therefore published the 2024 sequel,Taking Stock of Progress Against the Roadmapto Net Zero 2024. As with the original report, Aiiused data from Cascale, Worldly, and TextileExchange – with revised assumptions – torefresh the GHG estimate for the apparel sector.

Low-Carbon Thermal Energy

Technologies for the Textile Industry

With production rates increasing in manycountries, there is a need to adopt cleaner,more efficient, and low-carbon technologiesto mitigate climate impacts.

Low-Carbon Thermal Energy Technologiesfor the Textile Industry, commissionedby Aii and authored by Global EfficiencyIntelligence, examines the readiness of majortextile-producing countries to adopt lowcarbonheating technologies, assessing solarthermal; electrification (including electricboilers, heat pumps, and thermal energystorage); sustainable biomass; and naturalgas. It provides a detailed evaluation of eachtechnology, focusing on capital and operationalcosts, technological maturity, market growthoutlook, and climate and environmental risks.This is the first of a two-report series.

Low-Carbon Thermal Energy Technologiesfor the Textile Industry, commissionedby Aii and authored by Global EfficiencyIntelligence, examines the readiness of majortextile-producing countries to adopt lowcarbonheating technologies, assessing solarthermal; electrification (including electricboilers, heat pumps, and thermal energystorage); sustainable biomass; and naturalgas. It provides a detailed evaluation of eachtechnology, focusing on capital and operationalcosts, technological maturity, market growthoutlook, and climate and environmental risks.This is the first of a two-report series.

Landscape and Opportunities to Finance the Decarbonization of India’s Apparel Manufacturing Sector

India’s industrial sector accounts for about 25%of the nation’s carbon footprint, and the textileand apparel industry ranks among the highestcarbon-emitting industries in the world.

This presents both a challenge and anopportunity. With the right financing,manufacturing — specifically in the textileand apparel sector — can play a key role inmeeting India’s climate targets. Landscape andOpportunities to Finance the Decarbonization ofIndia’s Apparel Manufacturing Sector — createdin partnership with Development FinanceInternational (DFI) and with support from HSBC —explores how to mobilize sustainable financingand support the decarbonization of India’stextile and apparel industry.

This presents both a challenge and anopportunity. With the right financing,manufacturing — specifically in the textileand apparel sector — can play a key role inmeeting India’s climate targets. Landscape andOpportunities to Finance the Decarbonization ofIndia’s Apparel Manufacturing Sector — createdin partnership with Development FinanceInternational (DFI) and with support from HSBC —explores how to mobilize sustainable financingand support the decarbonization of India’stextile and apparel industry.

The Brand Playbook for Financing Decarbonization

Read more about this publication in the Sustainable Finance section of this report.

GFA Monitor 2024 Update

This GFA Monitor 2024 edition serves as a concise update gauging industry progress towards a net-positive fashion industry. Building on the Fashion CEO Agenda’s holistic framework, it highlights the critical need for social and environmental sustainability.

Aii contributed to the Monitor as an impact partner.

Aii contributed to the Monitor as an impact partner.

The Industry We Want

TIWW has partnered with Aii to estimate the garment sector’s annual greenhouse gas (GHG) emissions. The GHG metric is calculated using the most widely and representative data available: fiber volume data from Textile Exchange and GHG impact data from Cascale and Worldly.

Brand Commitment Working Group

Aii convened a motivated group of our brand partners to participate in a 90-day “sprint” effort to explore and align on action-oriented market signals to drive more rapid industry decarbonization. The group agreed on foundational elements of a commitment framework which Aii will integrate into our near and long-term strategies, particularly Sustainable Finance.

Carbon and Energy Performance Benchmarking

An essential part of the Industry Decarbonization Roadmap, which we will deploy with our partners at Cascale, is carbon and energy performance benchmarking. The initial focus will be wet processing facilities as the highest emitters.

Therefore, Aii has initiated an open and inclusive process to develop energy and carbon performance benchmarks for the apparel sector. The aim is to launch the benchmark in September 2025.